Willkommen zur German Website

Wir haben festgestellt, dass Sie möglicherweise die Global Seite bevorzugen. Bitte verwenden Sie die obige Auswahl, um Ihre Sprache bei Bedarf zu ändern.

Go to Global

- Produkte

- Lösungen

- Support

- Services

- Über uns

Willkommen zur German Website

Wir haben festgestellt, dass Sie möglicherweise die Global Seite bevorzugen. Bitte verwenden Sie die obige Auswahl, um Ihre Sprache bei Bedarf zu ändern.

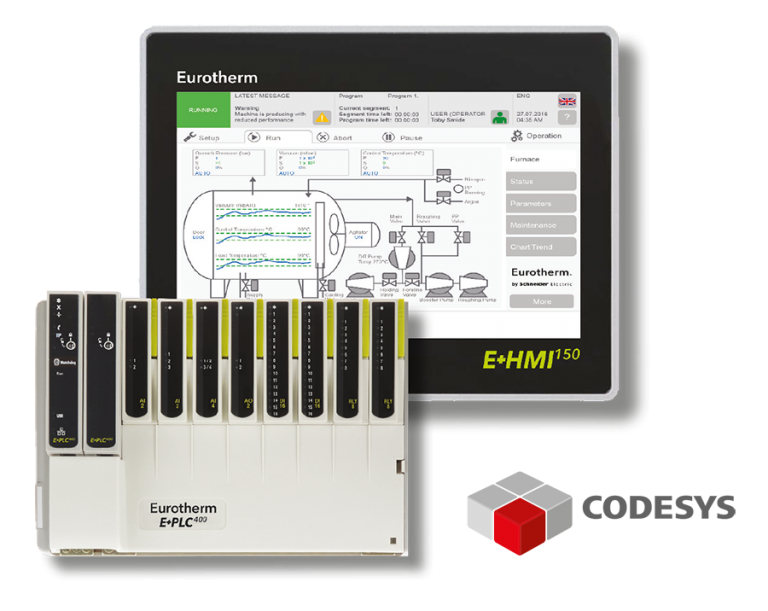

Advanced control, data management and visualization in a modular platform solution

DownloadThe machine feeds a consistent number of small metal components into a furnace where they are heat treated to increase their strength. The previous SCADA system included a PLC which had become obsolete, and the original program had been lost when the equipment had stopped working. The end customer requirement included modernization and re-engineering of the whole automation system.

A programmable logic controller was required to control the hopper, but some brands were dismissed for being overly complex or costly due to software licencing. The E+PLC400 modular controller was chosen for its free CODESYS® open platform which has programming, debugging and visualization, all in one tool. CODESYS integrated development environment is compliant with all IEC61131-3 languages, allowing for example, the electrical parts to be written in ladder logic and the analogue control to be created in function block diagram (FBD).

As the previous system program and related documentation were not available from the end user, Eurotherm™ application experts provided engineering support to help resolve the operation of the original machine. For consistent delivery of components to the furnace, the new hopper control system was designed utilizing maths equation functionality within E+PLC400 libraries to convert mass measurements to flow rate. Password management provided user level control and helped to protect the system integrator’s engineering IP (intellectual property).

“The support we received from Eurotherm application engineers enabled us to re-engineer the system in a faster time frame.”

“Our customer was trying to save space in the factory so they really benefited from the smaller cabinet design”