Willkommen zur German Website

Wir haben festgestellt, dass Sie möglicherweise die Global Seite bevorzugen. Bitte verwenden Sie die obige Auswahl, um Ihre Sprache bei Bedarf zu ändern.

Go to Global

- Produkte

- Lösungen

- Support

- Services

- Über uns

Willkommen zur German Website

Wir haben festgestellt, dass Sie möglicherweise die Global Seite bevorzugen. Bitte verwenden Sie die obige Auswahl, um Ihre Sprache bei Bedarf zu ändern.

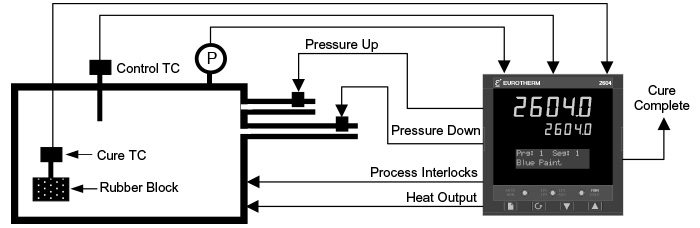

Vulcanisation is a process that is performed to harden rubber and improve its strength. The process, which is performed within an autoclave, is a function of temperature and time.Typical applications include automotive tyres, rubber mats and Wellington Boots. Vulcanisation includes the temperature profiling of both temperature and pressure. Traditionally, in most applications there is no indication of when the cure is complete. For this reason, to ensure that all components in the autoclave have been universally cured, process cycle times are usually longer than is necessary.

Temperature and pressure are both controlled by a 2604 programmer. The temperature control sensor is situated in free air and the control output can either drive a thyristor or a contactor.

Forcing air into or out of the autoclave using solenoid valves controls the pressure. The 2604 ToolKit functions are used to totalise the elapsed cure time and provide process interlocks.

This particular application involved the curing of the adhesive, which bonds the retread to the original tyre. A dummy load(rubber block)is placed inside the autoclave which emulates the temperature rise being achieved in the tyre. This load is placed in the coolest area of the autoclave. A sensor is inserted into the load and used by the controller to calculate the equivalent cure minute(ECM) value. When the total ECM’s reach a preset level, the curing cycle is complete.

The formula the 2604 needs to calculate is as follows:-

The ECM value is totalised every minute to produce a sum of the cumulated ECM’s. When the totalised value gets to its preset value a relay output is generated.