Need help choosing the right product?

Our tool will match the best product to your needs

Launch product selectorWelcome to the United Kingdom Website

We have detected that you may prefer the Global site. Please use the language dropdown above to change your selection if required.

Advanced control, data management and visualization in a modular platform solution

The components are treated inside the furnace for 20 hours, at temperatures of up to 1400°C, then plunged into a quench tank within one minute at the end of the cycle. The heat treatment process is regulated, requiring accurate measurement, tight control and reliable data acquisition to meet its stringent standards.

The old automation system was controlled by an obsolete 19” rack PLC which had become unsupportable and due for replacement. The traditional PLC’s PID control and programmer were very basic, so the furnace had always suffered from temperature overshoot. Data acquisition had been carried out via PC/SCADA, in the insecure CSV file format, and as the programmable logic controller was not capable of internal recording, the data could be lost if communications were interrupted.

The end user’s requirement included multiple control loops, 99 programs, 96 digital inputs, 48 digital outputs, data acquisition and a number of HMI screens with web browser access. Eurotherm control was the system integrator’s preferred choice, due to specialized PID control strategies, intelligent autotune, and advanced setpoint programming which, according to their engineering manager are “far superior compared to other PLCs and controllers”. Up until now, they had been using a third party programmable logic controller with separate Eurotherm precision PID controller to replace this kind of system but wanted to move to an all in one solution.

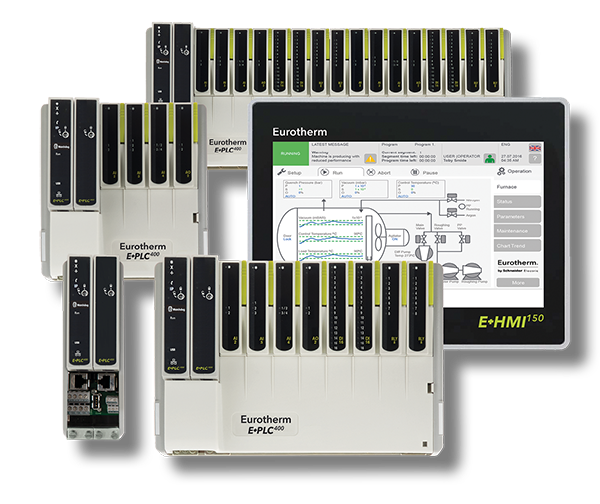

In this scenario, the E+PLC400 modular platform with E+HMI150 touch panel was their preferred solution, offering multiple control loops, setpoint programmers and segments, in combination with batch recording and PLC functionality. CODESYS® integrated development environment was also a familiar tool for the system integrator engineer.

Eurotherm ‘Cutback’ control and over-ramp suppression features helped to optimize heat treatment cycle times by minimizing overshoot during temperature changes. ‘Gain Scheduling’ and ‘Holdback’ functions were utilized to provide tighter heat control when needed during the cycle, and to hold the program until all the workpieces had been treated at the right temperature for the necessary amount of time. Thermocouple life function block was available to derive the working lifespan of thermocouples based on usage times and temperatures, and to indicate whether the thermocouples were still valid for use according to the AMS2750E standard.

Process data recorded in tamper resistant file format within internal memory could now be archived automatically as required, reducing the possibility of data loss due to communication drop-out, and aiding compliance to heat treatment data regulations.

Modular design, allowing up to 16 I/O modules along with Ethernet communications and web server functionality also satisfied the end user’s modernization requirements.

Eurotherm cutback and over-ramp suppression functions significantly minimize overshoot and instability, reducing the risk of over or under-heating workpieces. They also help to optimize energy usage and minimize production time and waste.

“I’ve been waiting for this product for a long, long time. There are many out of date PLC based systems in the field that require precision PID control. We can now replace these with E+PLC400 combination PLCs.”

The E+PLC400 combination PLC is suitable for use in Nadcap applications in all furnace classes A-E, as defined in section 3 of the AMS2750E standard. For more information, see Eurotherm Certificates.

Find out more about E+PLCProduct Selector

Our tool will match the best product to your needs

Launch product selectorContact Us