Bienvenido al portal web de Spanish

Hemos detectado que puede preferir el sitio Global. Utilice el menú desplegable de idiomas arriba para cambiar su selección si es necesario.

Go to Global

Bienvenido al portal web de Spanish

Hemos detectado que puede preferir el sitio Global. Utilice el menú desplegable de idiomas arriba para cambiar su selección si es necesario.

For the past 15 years, temperature, humidity, motor drive speed and interlocking control were provided by a Eurotherm 2500 modular controller and a third party PLC.

The company prefer Eurotherm PID control due to its fast acting precision control loops and gain scheduling function with extra PID sets, which they typically use to add extra cool from a two stage compressor when needed, for tight control to low setpoints.

Eurotherm E+PLC gain scheduling function provides six PID sets which can be specifically tuned to help reach different setpoints, for example, in control systems where the response to the cooling power is different from that of the heating power, or where operating conditions change in the process. Tightly controlled switching provides a smooth transition between tune sets, helping to minimize overshoot during ramping, and achieve steady state control.

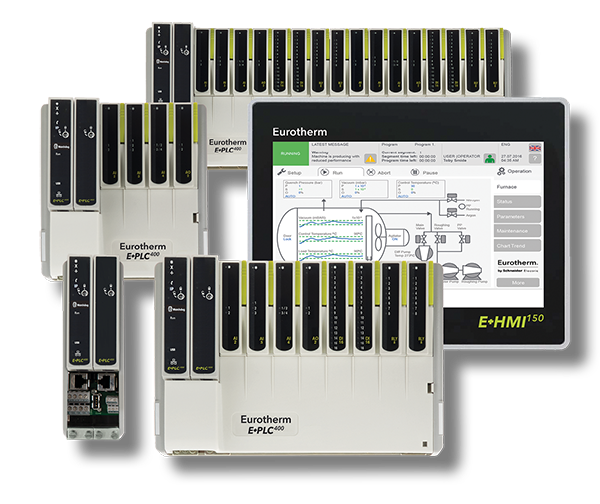

The E+PLC400 modular platform was chosen as a replacement solution as it combines Eurotherm unique PID control strategies, with programmable logic functionality and tamper resistant recording. As an off-the-shelf product it is also more easily maintainable compared to their previous PC based control systems which often required software upgrades that led to compatibility issues.

After the successful implementation of E+PLC products in a number of small environmental chambers, the solution was further utilized on larger environmental and climatic chamber control systems which were converted from a PC based measurement and control system to the E+PLC platform, due to the lower cost of the combined solution.

“PC based control systems typically limited system life to 5-10 years due to software upgrade compatibility issues – a big price hit for our customers. Using an off-the-shelf product like E+PLC400 will enable us to maintain them for longer, which better fits the life of the rest of the equipment”.

OEM engineer

“Eurotherm PID control in a PLC with recording – it’s game changing!”

OEM engineer

Recorded data can be retrieved from history files at any time using Eurotherm Review. For regulated industries, Eurotherm tamper resistant UHH file format is recommended.

Find out more