Besoin d'aide pour choisir le bon produit ?

Notre outil vous permettra de trouver le produit le mieux adapté à vos besoins.

Accéder au sélecteur de produitsBienvenue sur le site French

Nous avons détecté que vous préférez peut-être le site Global. Veuillez utiliser le menu déroulant ci-dessus pour modifier votre sélection si nécessaire.

E+PLC takes advantage of CODESYS, a leading platform which provides a proven, efficient engineering tool. Control and Visualization are built in the single integrated development environment (IDE), reducing the time and cost of implementing a system.

Engineers have the flexibility to develop sophisticated strategies and corresponding HMI functionality, with seamless integration between the two. Advanced Eurotherm algorithms can be readily selected from a library of easily applied function blocks. The resulting solution provides a standard, open platform for application development.

For ease of use and faster setup, the fully integrated CODESYS Visualization tool offers a modular facility to create enhanced views of the plant.

The CODESYS open platform approach facilitates a knowledge bsharing culture with numerous support forums.

IEC 61131-3 Programming Languages Supported:

Easy Engineering, Faster Commissioning:

Preservation of Intellectual Property

The flexibility of programming in CODESYS integrated development environment in combination with the precision control and maths functionality made E+PLC100 the most convenient solution

OEM Engineer

Access rights for individual users or user groups can be conveniently managed from within the IDE. For example, a push button visualization element could be configured to change controller settings.

Login functionality, password management and user management are available at runtime via the HMI. Password controlled access helps prevent unauthorized use.

Recipes are available for setting and watching control parameters. These can be saved, loaded and executed via visualization elements, and edited at runtime from within the CODESYS IDE. They can also be combined with the Eurotherm Batch Data Management function blocks to enable Batch processes.

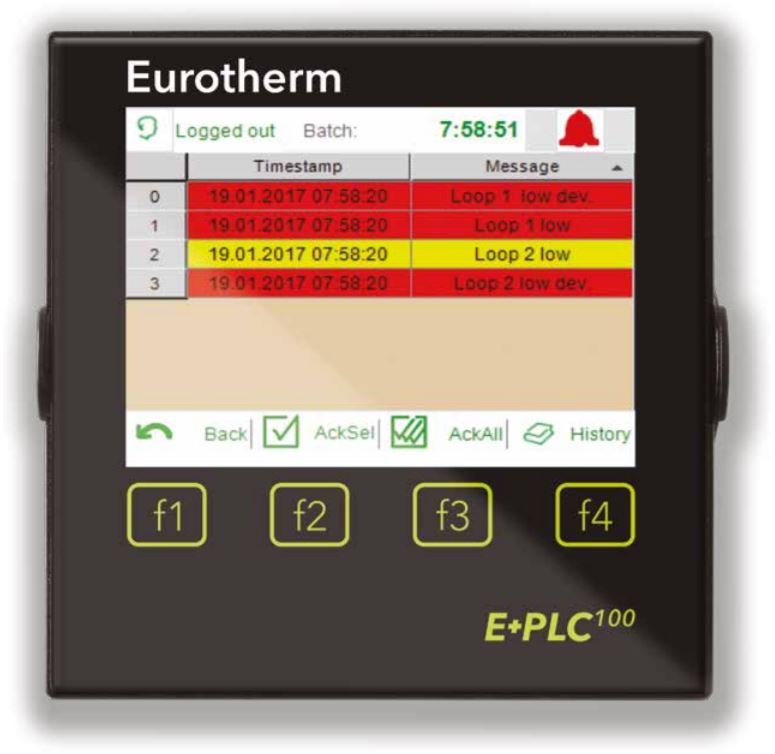

Alarms can be based on input signals or other PLC variables, and their conditions displayed on the HMI for acknowledgement by the user. Alarms can be grouped if required, and events can be triggered and processed from within any of the programming languages.

Triggered alarms can be recorded within Eurotherm UHH data files for historical purposes. This can be achieved utilizing function blocks in the Eurotherm Data Recording library.

CODESYS single engineering and visualization environment allows simple reuse of base code, enabling multiple E+PLC controllers to be combined into a single CODESYS project, or the screens of one project to be displayed on several different HMI devices.

CODESYS elements can be imported and exported between projects. The capability to import or export XML files in PLCopen format is also supported, allowing transfer of code to and from any PLC that supports this open standard.

The CODESYS debugging tool provides a number of useful features for validating applications, as well as real time access to running programs from the engineering environment:

“I’ve been waiting for this combined functionality for a long time. There are many out of date PLC based systems in the field that require precision PID control. We can now replace these with E+PLC400 combination PLCs.”

System Integrator Engineer

Sélecteur de produits

Notre outil vous permettra de trouver le produit le mieux adapté à vos besoins.

Accéder au sélecteur de produitsNous contacter