Information Manager

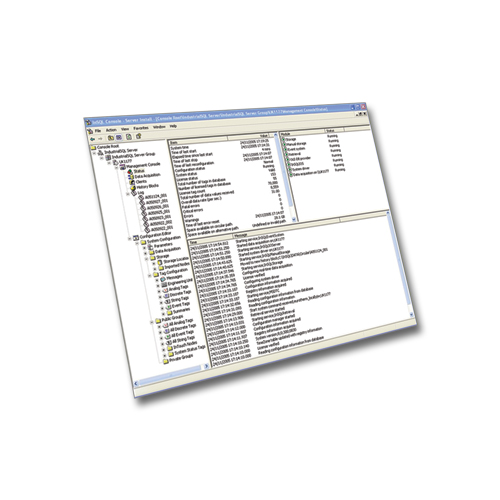

Information Manager Software

Information Manager provides system connectivity between the Eurotherm control network and the enterprise.

By directly accessing data, this real time historian package:

- Captures and stores all plant data all of the time

- Makes data accessible to entire organisation

- Uses embedded industry standard relational database

- Includes AVEVA Historian (formerly INSQL) software

- Up to 300 times faster than conventional relational database but only uses small amount of disk space

- Obtain data from Recorders using Review software

Description

Information Manager provides system connectivity between the LIN control network (via ARCnet and Ethernet) and the business environment. Enterprise clients systems can be distributed across multiple geographical and organisational boundaries, while maintaining access to any process value via the Operations Server or Information Manager. This structure enables applications to be distributed across the network and removes the need to duplicate data within each node.

The Information Manager combines the power and flexibility of a relational database with the speed and compression of a real-time historian package, providing integration between office and plant floor. It embeds Microsoft SQL Server™, providing universal data access, a powerful relational engine and tight integration with other Microsoft applications.

Engineers, maintenance managers and plant operators can view, analyze and present real-time, historical and alarm information using ActiveFactory client applications. Other off-the-shelf software that supports SQL/ODBC interfaces can directly read data from the pre-built tables.

The database and stored procedures are automatically installed requiring no prior knowledge of relational databases or SQL. The Information Manager incorporates powerful, pre-defined queries enabling users to search and find data. This facilitates the understanding of the complex relationships and correlation between physical plant, manufacturing operating conditions, process events, product quality and production efficiency.

Features:

- Real-time and historical plant information accessible to entire organisation

- Minimizes storage space and controls volume of data retrieved

- Embedded Microsoft SQL Server™ provides standard access via SQL queries

- OPC and SuiteLink LIN protocol I/O driver with in-built Server Security

- Totally integrated with Project Developer Database

- Integration with relational alarm database

- Contains Wonderware® IndustrialSQL™ server

- All plant data is acquired and stored at full resolution e.g.

- Real-Time data (current plant values)

- Historic data (long-term historian)

- Event data (operator changes)

- Alarm data (plant and system alarms)

- Summary data (e.g. hourly averages, maximum)