E+PLC100 Combination PLC

Advanced control, data management and visualization in a single box solution

- A compact combination PLC

- Precise control, setpoint programmer and tamper resistant recording fully integrated within a PLC application

- Minimizes engineering and commissioning costs while maximizing process performance

- Inbuilt advanced PID and setpoint programmer functions

- Continuous and batch recording

- Visualization remotely browsable from smart devices

Description

E+PLC100 is a combination single box PLC designed to meet the stringent regulatory requirements of thermal and other advanced manufacturing industries.

By utilizing the open industry standard IEC61131-3 CODESYS® platform, E+PLC enables simplified engineering through a single integrated programming and visualization environment. Includes advanced function block libraries for:

- Heat treatment applications

- Control and data recording

- ‘OEM security’ and customization Eurotherm’s unique PID control functions are built-in, enabling faster commissioning and tighter control of the overall process, as well as easing conformance to regulatory and end-customer requirements, including:

- 6 PID sets to help maintain tight control at different setpoints

- Intelligent auto-tune for optimal control and commissioning

- Specialized cutback function for overshoot control Data management embedded in E+PLC helps manufacturers meet strict regulatory process data requirements, including:

- Tamper-resistant file format .uhh (a superior alternative to editable .csv solutions commonly found in PLCs)

Ethernet communications offer connectivity to IIoT (Industrial Internet of Things) and Industry 4.0 technologies, such as EcoStruxure Manufacturing Compliance Advisor (EcoStruxure Manufacturing Compliance Advisor).

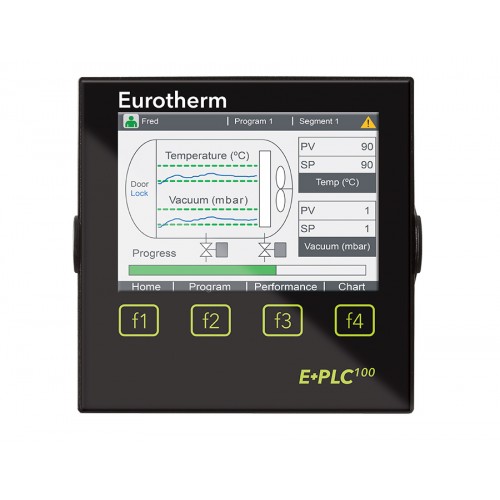

To assist with operational efficiency, E+PLC100 includes a fully configurable touchscreen HMI, as well as an embedded webserver for remote viewing on mobile devices.

Specification

| Autotuning PID | Ja |

|---|---|

| Setpoint Programmer | Yes |

| Secure Recording | Yes |

| Archiving Strategy | Ja |

| Batch Management | Yes |

| Programming Platform | CODESYS (open) |

| Programming Languages | FBD, IEC61131-3 compliant, IL, LD, SFC, ST |

| Product I/O Format | AI(4), AO(3), DI(3), DO(2), RLY(3) |

| I/O Expansion Method | Modbus |

| Communications | FTP, Modbus, TCP/IP (Master/Slave) OPC-DA via PC based software |

| AMS2750F | Yes |

| Recording Duration (approx) | Based on 4 chs at intervals of: 1s 13 days 10s 130 days 20s 260 days 60s 2 years |

| Panel HMI (Protocol) | Built in |

| Web Visualisation | Ja |

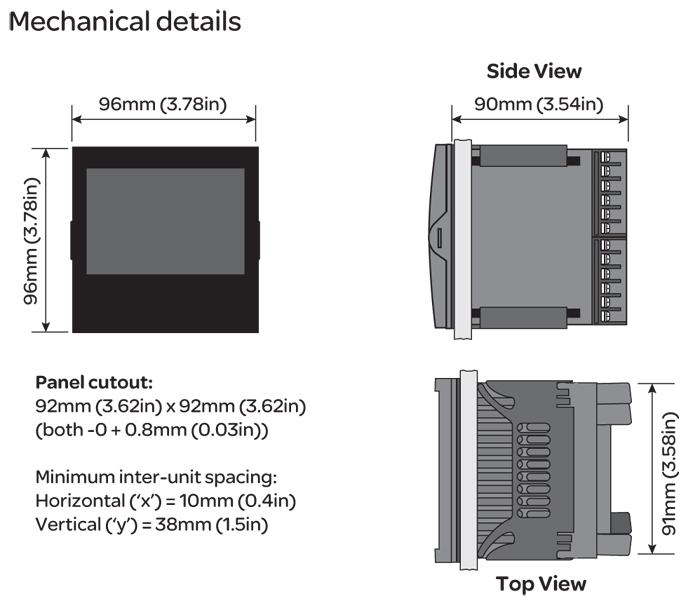

| Mounting | Panel |