Need help choosing the right product?

Our tool will match the best product to your needs

Launch product selectorWelcome to the USA Website

We have detected that you may prefer the Global site. Please use the language dropdown above to change your selection if required.

Precision power and process control

Glass Fibre

| Display Glass

|

Glass processes that rely on platinum equipment to apply heat to the melt have existed for many years, but due to long campaign lifecycles and resistance to change, some manufacturers are still using old technology. In continuous processes your only window of opportunity to make step change improvements is during a new build or a shut down, so you need to be sure your choice of equipment provides for all your future needs.

Over the next few years, incoming energy and environmental regulations will likely affect your business, as will changing customer demands. Will you be able to meet them if you stick with traditional equipment and design?

• Is your current system more than 25 years old?

• Are you in your second campaign and nearly due for furnace refurbishment?

• Do you need to meet Arc Flash and Power Factor legislation?

• Will you need to increase production during the campaign?

• Do you need to improve your energy and environmental KPIs (Key Performance Indicators)?

Some time ago, Eurotherm by Schneider Electric recognised that traditional equipment and system design was becoming a barrier to making improvements. That’s why we took a fresh view from end-toend. The result is an alternative design approach combining best of breed equipment with expertly applied system layout and know-how, solving a vast majority of long standing traditional design issues.

A variety of financial and efficiency benefits can be related to Eurotherm’s ground breaking methods which apply power to platinum heating devices in an innovative way. Depending on the amount of equipment you want to retrofit, we offer different improvement options that can substantially reduce energy usage in platinum heating systems, and greatly improve the throughput and quality of the product.

Platinum heating equipment requires a high level of electrical energy to melt the glass, but in traditional power system design, it’s common for electrical noise to cause additional heat loss in the cables and busbars of the system itself.

You’re paying for that unnecessary heat waste, plus you’re at risk of paying energy taxes and fines for going over your tariff, and failing to meet government or utility regulations. What you really need is a system where the applied energy is optimally utilised to melt the glass via the platinum heater, rather than being wasted and adding extra costs to the electricity bill.

Reducing electrical noise involves using the latest technological breakthroughs so Eurotherm has formed best of breed partnerships with high-end equipment suppliers. This combination of expertise allows us to provide a range of up-to-date, exceptionally low noise systems to suit your budget and installation.

*Possible savings depend on the state of the installation before retrofit. Savings shown are based on typical savings seen in previous retrofit platinum heating applications.

In older plants, traditional electric power control systems are often operating near their supply capacity, limiting your ability to increase throughput and output. What if you need to meet growing customer demand?

Sticking with older technology will not give you the flexibility to increase productivity without upgrading your electrical distribution system, nor improve the quality of the product.

The energy saving aspects of a Eurotherm system are so substantial that they can make productivity expansion possible within the bounds of your current electrical supply. For example, once installed, the amount of energy saved could give you the option to increase the size of platinum heating equipment or even add another production line.

Vibration and poor temperature uniformity across platinum heating devices are common causes of damage and imperfections in glass products.

The way a Eurotherm system applies power in combination with the electrical-noise reducing design, has a beneficial effect on the temperature uniformity across the platinum heating equipment and substantially decreases vibration. Precision control also maintains the temperature at the optimum level. The result is a consistent pull of high quality glass with less breakage. It becomes a highly repeatable process, needing less historical knowledge and input from an operator.

Platinum heating devices are high value assets so you want them to last as long as possible. In older style power system design, the weak points are the connections where small cracks and erosion can occur due to vibration.

Our low noise system greatly reduces the cause of damaging vibration so platinum parts last longer. Think about the possible savings over the lifetime of a campaign in your application.

As the platinum equipment is replaced less often, maintenance time is saved. In a large plant this could amount to weeks or months saved over the entire campaign.

Whether you call it Industry 4.0 or the Industrial Internet of Things, your system needs to be ready to connect with and utilise these evolving technologies.

Pulling data from multiple systems can be a challenging manual task. How many of your personnel are wasting time generating reports by hand?

Connectivity of multiple systems into a single server greatly improves your ability to retrieve data for analysis and reporting. Eurotherm solutions offer a range of industrial communication protocols to transfer data from different factory systems to one place and connect with IIoT technologies. Historical and real-time data can be brought together in a single historian where it is easily accessed retrieved and analysed using accompanying tools by all levels of personnel.

Optimising your process is difficult if you can’t see what’s going on, so it’s important to invest in a system that can acquire the data you need easily and reliably.

For data analysis you need accurate measurement of key parameters, dependable recording, archiving and retrieval of data, plus an easy way to report your findings.

A Eurotherm process control system is based on well-designed products that provide high accuracy measurement and signals even in electrically noisy environments. Data is collected at the point of measurement and recorded in internal memory from where it can be archived automatically to a historian server. Once you have data you can start analysing in real time or historically and see if improvements are working.

Benchmarking your process will enable you to spot previously unforeseen issues caused by ageing equipment, different batches of raw materials and different machine operations.

From plant personnel carrying out operational CI (Continuous Improvement), to corporate management for ERP (Enterprise Resource Planning), demonstrating your KPIs is much easier with our industrial reporting package. Reports can be generated individually or automatically via a template directly from the historian, and then pushed to the person who needs it by hand or automatically triggered on an alarm or event.

Comparing live process data with historical benchmark data allows you to:

Glass plants are electrically noisy environments and regulations exist to limit their detrimental effects on the electricity supply. A key parameter measured by utility companies is Power Factor (PF) and industrial consumers with low PF are often forced to pay higher tariffs.

Traditionally designed platinum heating systems often don’t provide a high PF so correction is required in the form of costly capacitor banks.

Eurotherm’s power control methods, specially designed equipment, and attention to component, cable and busbar layout can greatly improve the PF compared to a traditional system. The improvements can result in a lower electricity tariff, less risk of fines and negate the need for correction capacitors.

High current circuits require large components and a number of safety devices to prevent and protect from arc flash events, but a better solution is to reduce the risk in the first place.

Rethinking the entire system design allows our solution to reduce the amount of current in the circuit. This means the size, cost and number of electrical safety devices is reduced and more importantly the risk of arc flash occurring is much lower.

Taking the leap to a more future proof manufacturing environment needs a different approach to technology and design. Plant personnel will need to embrace new concepts, so change acceptance is an important consideration.

Depending on the current state of the plant, different solutions are available which will most likely involve changes to transformer location and busbar layout. These step changes in design are necessary to reap the energy and efficiency benefits for fast ROI (Return On Investment), so we’ll work closely with your engineering teams to ensure their understanding and acceptance.

Eurotherm platinum heating projects are designed by a team of glass expert engineers and partners, covering all levels of engineering support. Understanding your plant specific electrical, mechanical and processing concerns, we can offer advice on equipment choice, location and layout. We can also assist with the mechanical aspects of mounting and installation. On top we add our power and process control expertise, providing you with a highly efficient system from end-to-end.

Engineering expertise

As well as offering project design and installation, we also provide the following :

Traditional designs use air cooled transformers which take up a lot of space and need to be situated a relatively long distance away from where the heating power is actually needed. The long copper busbars and number of junctions required to run power to the heater are both expensive to install and add extra costs in wasted energy.

With Eurotherm’s solution, the use of water cooled transformers situated very close to the heater means the busbar lengths are greatly reduced and fewer junctions are required. Financial, environmental and space savings are achieved through reduction of expensive copper parts, related industrial waste, and no need for the large external transformer room along with the associated air conditioning.

EPower™ and EPack™ power controllers provide intelligent networked control for your electric heating applications. Measuring, monitoring and controlling your energy plant-wide, while utilising selectable firing modes to reduce electrical noise in the system, results in optimised energy usage and lower bills, within the bounds of your energy tariff. EPower Power Controller

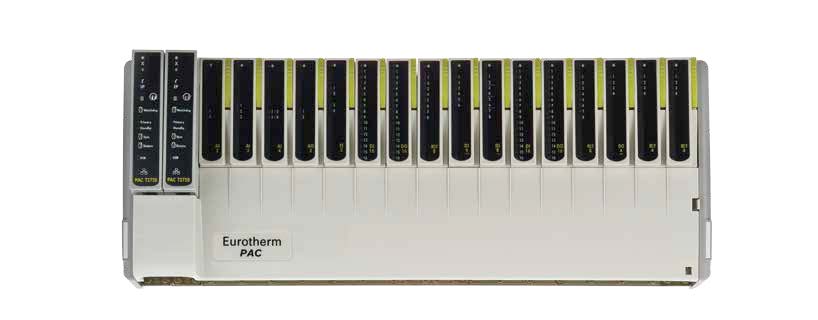

Typically this is based on Eurotherm T2750 PAC (Programmable Automation Controller) in combination with EurothermSuite™ or Wonderware™ System Platform. As well as offering dual redundancy, choosing this off-the-shelf product instead of a PC based control system removes the hassle of operating system upgrades and software incompatibility during a campaign.

Possible improvements and savings are dependent on the age, condition and design of the existing system. The older the design and the more you can change, the better the savings will be. Think about the possible operational savings over the lifetime of the furnace. The good news is our team of glass experts are available to carry out energy surveys on your production lines without interrupting your process. Just contact us in advance of your refit and we’ll calculate your potential savings.

Product Selector

Our tool will match the best product to your needs

Launch product selectorContact Us