Need help choosing the right product?

Our tool will match the best product to your needs

Launch product selectorWelcome to the USA Website

We have detected that you may prefer the Global site. Please use the language dropdown above to change your selection if required.

The semiconductor fabs of today face ever increasing pressures to reduce time to market and minimize costs

EtherCAT™ is an industrial Ethernet technology. Open connectivity with EtherCAT supports industry standardization and helps reduce time in design and build with common connectivity across devices.

Semiconductor manufacturing solutions >

EPack power controller for semiconductor fabrication >

Mini8 temperature controller for semiconductor processes >

Operational resilience in semiconductor fabrication >

Sustainability for semiconductor manufacturing >

Custom solutions for OEMs >

Explore our semiconductor application expertise >

Download Semiconductor Brochure >

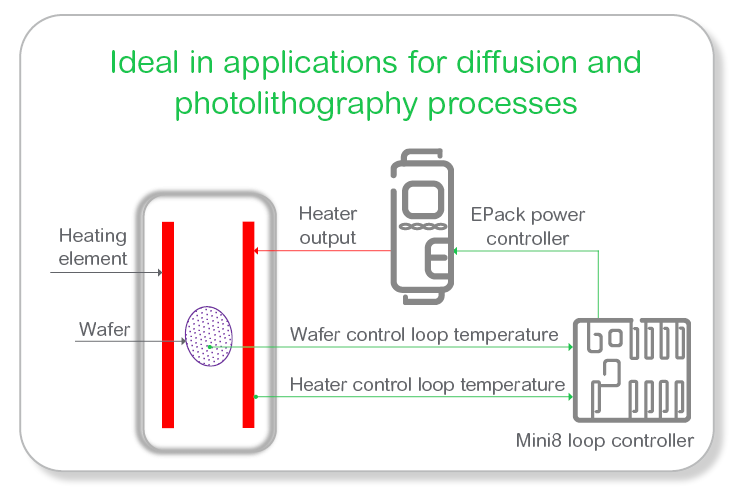

Founded in November 2003, the ETG group is comprised of key user companies and automation suppliers including Eurotherm, who have joined forces to support, promote and advance EtherCAT technology. The ETG’s EtherCAT power profile sets the boundaries by which an EtherCAT power or temperature solution should be selected. It supports the industry’s move from analog to digital devices for increased connectivity, allowing for scheduled and proactive maintenance. The Eurotherm EPack compact SCR power controller and Mini8 loop controller are EtherCAT-ready and meet the ETG power profile and temperature profile specifications. This pre-validation can shorten deployment time and mean faster build time.

“One of the most widely discussed industry phenomenon has been the slowdown of Moore’s Law…which posits that the number of transistors doubles every 18-24 months…Chips are now smaller, denser, and more powerful than ever before. Relative to other industries, Moore’s Law has propelled the semiconductor industry to achieve an unparalleled pace of innovation.”

Source: Harnessing the power of the semiconductor value chain

Semiconductor fabs still need to be resilient and adaptable for these changes. EtherCAT helps improve market agility to meet increasing demands.

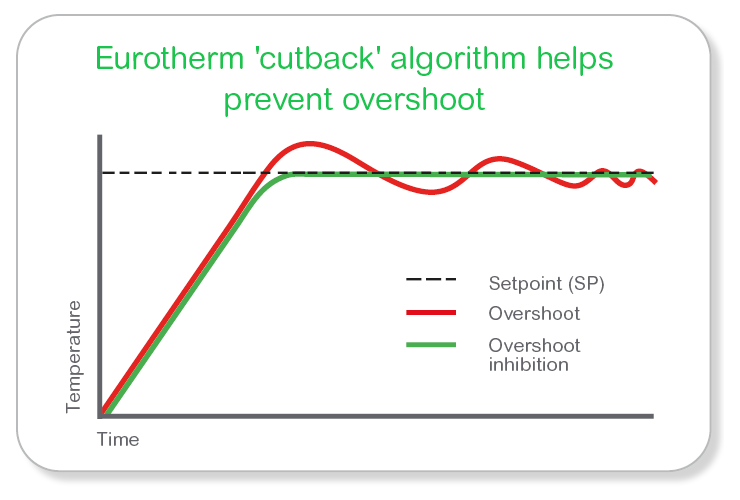

Precision PID control has embedded algorithms to tightly control temperature, so setpoints are reached with minimal overshoot during ramps and the process variable stabilizes faster. When operating temperatures are outside the desired setpoint, the result is wasted time and energy, defects from under or over-heated material and possible scrap product. In Eurotherm products the ‘cutback’ algorithm helps prevent overshoot.

Eurotherm has spent over 50 years perfecting these kinds of algorithms, along with advanced autotune features that automatically set desired parameters in the PID control loops to suit the application. Taking care of this often manual task, achieves automatic efficiency and repeatability, even compared to the most sophisticated model-based control strategies, which are not able to compensate for a badly tuned process.

Product Selector

Our tool will match the best product to your needs

Launch product selectorContact Us