Need help choosing the right product?

Our tool will match the best product to your needs

Launch product selectorWelcome to the USA Website

We have detected that you may prefer the Global site. Please use the language dropdown above to change your selection if required.

Published in Glass Worldwide, November 2013.

With its origins in the West Sussex town of Worthing in the UK, Invensys Eurotherm has emerged as a leading expert in the development of process control solutions for primary glass manufacturers throughout the world. This innovative company’s history, current activities and priorities for the future are addressed in the following exclusive interview. John Wallis reports.

Glass process control forms an essential part of the Eurotherm DNA, fuelling the development of one of the first microprocessor-based process controllers (type 6350).

At the start of the company’s journey, former Group Technical Director, Professor George Turnbull commented: “I was quite proud of our position in the glass industry during the early days. We were able to take on and beat the big guys, Foxboro and Honeywell in particular. We worked all hours of the day and night but we were totally dedicated, in a situation where common sense deemed it impossible.”

Invensys Eurotherm has built on this legacy and now holds a prominent position in global glass process control, achieved through investment in industry expertise, backed by product innovation and project execution. Many customer problems are solved via a comprehensive product portfolio, from specialised sensor technology to drives, process and power control and ultimately delivering real-time information through SCADA and MES solutions.

“The glass industry is full of people who like doing high quality work” explains Rob Rennie, President, Energy Controls. “Maybe it’s the nature of the product they’re making… you can see any errors really quickly!” According to Mr Rennie, Eurotherm enjoys this because the business is about building high quality, high precision and high performance technology. “So when you have the chance to work with people who use such equipment and are interested in really good quality, we genuinely enjoy it.”

Dealing with such prestigious names as Saint-Gobain and Pilkington, over the years Invensys Eurotherm has built up extensive experience in the international flat, hollow, fibre and TFT glass sectors.

It was in 1965 that Gerry Martin (Managing Director), Jim Hartnett (Chairman), Mike Somerville (Technical Director) and Jack Leonard (Sales Director) set up Eurotherm Ltd in Worthing, West Sussex. Having realised their goal of being profitable within six months, the UK company achieved annual profits of more than £1 million before the end of the decade. Businesses were established in the USA, Germany, France and Switzerland, while others in Hong Kong, Italy, Japan, Korea, Holland, Belgium and Austria soon followed. Eurotherm went to the London Stock Exchange in 1978, the initial public offer having been massively oversubscribed.

Gerry Martin and Technical Director, George Turnbull shared a keen interest in glass processing. Together with his R&D team, Professor Turnbull developed one of the first microprocessor-based process controllers for the industry and in his later life, Gerry Martin co-authored a paper on glass entitled ‘The Glass Bathyscaphe – How Glass changed the World’.

Building on this solid foundation, Invensys Eurotherm has developed a range of solutions to address specific demands for high quality temperature control, mid-sized programmable automation systems and environmentallyconscious power controllers. By continuing to build its wide base of glass manufacturing knowledge, the company has been able to supply innovative projects with a global reach.

Over the years, such key individuals as George Turnbull, John Shackleton and Brian Chessell lent their names to a number of Eurotherm start-up companies that became extremely successful over many years. As technology evolved, however, Eurotherm became aware that the product range began to lend itself to many similar requirements and therefore, a number of these companies – Eurotherm Recorders (formerly Chessell Ltd), Eurotherm Process Automation (formerly Turnbull Control Systems Ltd) and Eurotherm Controls Ltd (formerly Eurotherm Ltd) – were merged again to become Eurotherm Ltd. The drives business, Eurotherm SSD Ltd (formerly Shackleton Systems Drives

Ltd) was sold to Parker Hannafin Ltd.

An important part of the Invensys group for the past decade, the business still trades on the established Eurotherm brand identity, while Invensys provides stability and important reassurance to customers. “It gives everyone security and a fantastic foundation” says Rob Rennie. “However bad the recession was, this company would never fold.” Mr Rennie was formerly Managing Director and has been President of the equipment business for four years. “Every year, we have invested more and more on R&D, regardless of the economic situation” he adds.

Invensys recently accepted a takeover bid from the French company Schneider Electric. “This move will be great for Eurotherm and will provide access to an even largerrange of hardware” Rob Rennie confirms. “These are very exciting times!”

Another key reason for the company’s current high profile in the international glass manufacturing sector was the appointment six years ago of industry expert, René Meuleman. Having studied electrical engineering, Mr Meuleman worked initially in the paper industry before joining Dutch glass producer, Vereenigde Glasfabrieken in Maastricht. He soon built a broad knowledge and experience in the design and development of glass container electronic quality control equipment and was involved in the implementation of the first generation PLC and DCS systems, as well as electronic timing systems for IS machines.

Another key reason for the company’s current high profile in the international glass manufacturing sector was the appointment six years ago of industry expert, René Meuleman. Having studied electrical engineering, Mr Meuleman worked initially in the paper industry before joining Dutch glass producer, Vereenigde Glasfabrieken in Maastricht. He soon built a broad knowledge and experience in the design and development of glass container electronic quality control equipment and was involved in the implementation of the first generation PLC and DCS systems, as well as electronic timing systems for IS machines.

René undertook several modelbased predictive control projects, as well as being involved in objectoriented engineering method developments. Subsequently,he managed process control development within the BSN group and was ultimately responsible for European plant process control and forming electronics within the Owens-Illinois group.

Today, he is Invensys Eurotherm Global Glass Industry Technical Leader, focusing on process and power control solutions, energy management and MPC for end users, OEMs and solution providers. His motto is: “One cannot do without innovation, even in the glass industry. Be conservative during the campaign but be extremely innovative during builds and rebuilds.”

According to Rob Rennie, René Meuleman’s instant technical knowledge has been invaluable. “Although we have always thought of ourselves as insiders in the glass industry, perhaps we weren’t always acting like it” he suggests. “Glass was being discussed in our company all the time but with René on the team, we have been able to contribute even more to the glass community. It has been deliberate to be more visible and this is very much part of the long-term plan. As well

According to Rob Rennie, René Meuleman’s instant technical knowledge has been invaluable. “Although we have always thought of ourselves as insiders in the glass industry, perhaps we weren’t always acting like it” he suggests. “Glass was being discussed in our company all the time but with René on the team, we have been able to contribute even more to the glass community. It has been deliberate to be more visible and this is very much part of the long-term plan. As well

as advertising and writing articles for Glass Worldwide and being at conferences and exhibitions, it’s all about listening. We are not a very secretive company and we like to share what we know.”

Recently, René Meuleman was recognised at the Invensys Circle of Excellence Awards, an annual event that only the best, highest performing employees are invited to attend. “René earned his right to be there, winning what we describe in-house as the ‘best supporting actor’ award” Rob Rennie explains. “Most people in attendance are from the salesforce but René got there because everyone voted for him. And when the sales folk were voting for him, that says it all!”

A lot of René Meuleman’s thinking has gone into the E-Pack product innovation, which is basically a smaller version of E-Power. “René knows instantly whether an idea is good for glass or bad” Rob Rennie adds.

Today, Invensys Eurotherm manufactures special custommade high temperature sensors and thermocouples, recorders and recorder/controllers, a diversity of high accuracy temperature controllers, programmable automation controllers (medium size DCS) and a wide range of SCR power controllers (silicon-controlled rectifiers).

Eurotherm leverages the vast experience of the Invensys Group by selecting from a comprehensive list of solutions/products available from sister companies. These include Scada-HMI-MES systems from Wonderware, Triconex safety systems, Simsci MPC solutions, IMserve metering and energy management and Foxboro-Eckhardt field devices.

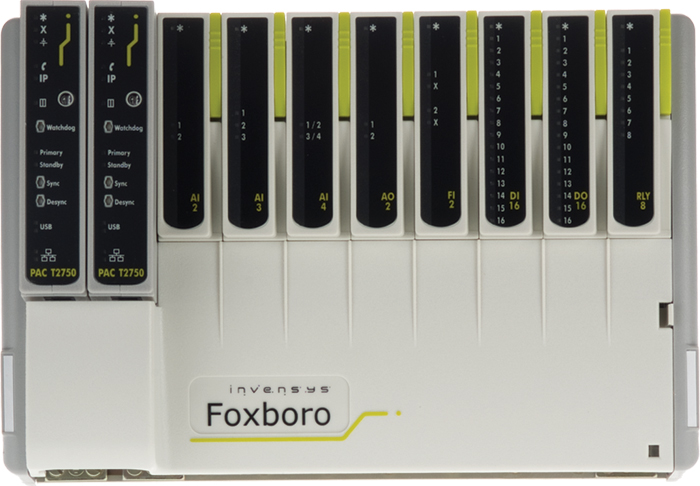

The PAC range of products (T2550/T2750) and SCR power controllers (EPower) represent major Invensys Eurotherm products sold to the glass industry. The recent launch of the EPack compact SCR power controller has already indicated that it has a strong future in controlling electrical heating in forehearths, medium sized bushings and drain control.

The PAC range of products (T2550/T2750) and SCR power controllers (EPower) represent major Invensys Eurotherm products sold to the glass industry. The recent launch of the EPack compact SCR power controller has already indicated that it has a strong future in controlling electrical heating in forehearths, medium sized bushings and drain control.

According to René Meuleman, a number of the company’s discrete (standalone) controllers are still continuing to operate successfully and control glass furnaces and forehearths. “The technology has developed, however, allowing a greater level of process control, data capture and information reporting.”

The PAC (Programmable Automation Controller) solution offers a high level of flexibility in configuration and open control protocols and is naturally matched with the HMI systems (Esuite or Wonderware system platform). “The in-built accuracy in a PAC T2750 and an open realtime database driven software platform provides the necessary

flexibility and future adaptability to the changing needs of the industry” Mr Meuleman confirms. “We strive to keep to our promise of leading the way in glass manufacturing solutions.”

Eurotherm’s existing business is divided between offering individual products and full system solutions. “Sometimes customers want the hardware specifically because of its features, as in the case of E-Power but this arrangement will change because we want to do even more for customers. Energy is a major problem and we think we can do more for them and that will develop.”

Eurotherm’s existing business is divided between offering individual products and full system solutions. “Sometimes customers want the hardware specifically because of its features, as in the case of E-Power but this arrangement will change because we want to do even more for customers. Energy is a major problem and we think we can do more for them and that will develop.”

E-Pack and E-Power products are cited as good examples. On first impression, they are considered better replacements for previous generations but according to Rob

Rennie, both are capable of generating valuable energy savings. “E-Power is fundamentally a power control platform with immense flexibility; I don’t think there has been an engineer yet who’s found its boundaries.”

Sometimes customers want Eurotherm to work with other suppliers and Rob Rennie has no problem accommodating this requirement. “We would never consider engineering a project for a customer without our own equipment but if the customer wants us to consider other factors, then we will, of course.”

Rob Rennie has worked for Eurotherm for 27 years and although there have been a number of important management changes, some valuable consistencies continue to run through the organisation. “We have the same engineering teams going into some of our best customers to replace equipment that they themselves installed at the last shutdown” he says. “They have the huge advantage that they managed the application last time and they are doing it again 14 or 15 years later. The customer’s job might be very complicated but it’s OK because we know each other so well.”

In many respects, Eurotherm is proud to be significantly different to many other businesses, a relatively big company but still a niche player. “Getting it right and keeping performance high is what we do. Glass is one of those niches and we’re really proud of it.”

Customer support investments in North America, India and Australia are among the company’s long-term priorities, as it looks to reinforce the global services provided.

Although the UK is very much the centre of excellence, Invensys Eurotherm engineering centres throughout the world can be used to perform this work. “Much of the work is step and repeat and once you know how to build it, complex integration elements can be handled from the UK.”

Rather than investing in one country or another, however, Rob Rennie prefers to describe Eurotherm’s strategy as investing in a ‘global glass team’. If an engineer is located on the west coast of North America for example, that person will often follow a customer around the world. “Customers like the fact that they’ve spoken to someone locally and then t

ey may want them to go to a different plant elsewhere… you follow your customer” he explains.

“The company structure is flexible enough to allow this to happen; we don’t care about order recognition and where the order is placed – that’s dealt with in the back office. Get the order, serve the customer, execute perfectly and then we’re happy.” This strategy also helps Eurotherm employees to gain optimal global knowledge about their customers.

There is good glass competence in every Eurotherm office and there are immediately accessible experts that can be flown anywhere instantly.

“Glassmaking is a complex process, where a combination of numerous chemical processes during melting and refining, combined with high process temperatures and difficult-to-measure process properties all lead to the need for complex control solutions” says René Meuleman. “Glass process equipment is very capital-intensive but benefits derived from the regenerative processes have made glassmaking more energy-efficient over time.”

For many years, the industry strived for refractory quality improvements and longer furnace lifespans. This has now been realised, resulting in furnace campaigns that now last 15 years or more. “In order to control these assets, it is important to use reliable and accurate equipment” Mr Meuleman continues. “Like the furnace, attached systems have to last for at least the same time without obsolescence issues. The product specifications and obsolescence policy of Eurotherm fits these demands well.”

According to Eurotherm’s glass industry expert, however, long furnace campaigns can stifle innovation and flexibility. “An interesting change of direction has resulted, due in part to the availability of electrical boosting systems, enabling higher pull rates but with associated shorter furnace lifespans” he contends. “It is possible to produce the same amount in a shorter time and a side benefit is the opportunity to adapt to new technologies during more frequent furnace repairs. The industry is changing from being very conservative to being more open to innovations that ultimately lead to more value being realised by the manufacturer.”

Invensys Eurotherm is confident that its latest developments can satisfy the glass industry’s need for additional improvements. “Providing better solutions and being a ‘trusted advisor’ to customers is very important to growing successful relationships” René Meuleman suggests. “We not only invest in process control knowhow but also glass manufacturing expertise to ensure that we can translate real-life problems into process control solutions.”

Rob Rennie agrees. He believes that Invensys Eurotherm has some great products and the right people in place in terms of engineering. “There are some industries where you look for a short-term hit but the biggest barrier in the glass industry is the need to hurry up and be patient!” he contends. “Put in the long hours and the customers will stick with you but it takes a long time. And because we are a patient company, we see that as a genuine advantage… we like the glass industry and are very committed to it” Mr Rennie concludes.

Product Selector

Our tool will match the best product to your needs

Launch product selectorContact Us